Strategies for Ford to contribute in US last mile

GOAL

Understanding and capturing compelling solution areas for US last-mile parcel delivery informed by customer research, emerging technology research at Ford, and its impact on current programs and provide subsequent teams and FordPro leadership with an informed point of view (POV) to support direct work with customers.

Understanding and capturing compelling solution areas for US last-mile parcel delivery informed by customer research, emerging technology research at Ford, and its impact on current programs and provide subsequent teams and FordPro leadership with an informed point of view (POV) to support direct work with customers.

Team

I worked with two researchers, one Industrial designer, a developer, and two activation engineers.

I worked with two researchers, one Industrial designer, a developer, and two activation engineers.

Role

Immersion

Creating provocations for research

Listen in on user interviews to understand the context firsthand

Secondary research

Immersion

Creating provocations for research

Listen in on user interviews to understand the context firsthand

Secondary research

Define & Ideate

Ecosystem maps

User journeys

Facilitating ideation and prototyping workshops

Ecosystem maps

User journeys

Facilitating ideation and prototyping workshops

Delivery

Design assets for both UI and physical concepts

Future state journey maps

Strategy deck

Design assets for both UI and physical concepts

Future state journey maps

Strategy deck

TIMELINE

This was a 4-month long project, starting with initial research and design, followed by developing solutions, refining product strategy, and ending with a design hand-off to our cross-functional teams comprising of design studio, product strategy, product development and Dford.

CHALLENGES AND PROJECT CONTEXT

Just to give some context this is a B 2 B 2 C landscape, where Fordpro sells products and services to businesses or customers, which are operated by a workforce on the ground to then supply goods to the end consumers. So there are a lot of different stakeholders in this chain

In addition to that we faced two fundamental challenges on this project. First was a catch-22 situation, we were not allowed to talk to customers without having a point of view, but to have a point of view we needed to talk to customers, second, the pandemic had just begun and we had to do this all remotely.

In addition to that we faced two fundamental challenges on this project. First was a catch-22 situation, we were not allowed to talk to customers without having a point of view, but to have a point of view we needed to talk to customers, second, the pandemic had just begun and we had to do this all remotely.

Key Customers

UPS, FedEx, DHL, and Amazon are more than half of the US industry's revenue.

UPS, FedEx, DHL, and Amazon are more than half of the US industry's revenue.

These top four players have existing partnerships with OEMs. Ford wanted to understand what solutions could it offer to logistics companies.

Mileage and Range requirements

The top four have long-range needs.

This was in line with the program's objectives in terms of wattage. We looked at what affordances enable in terms of digital as well as physical experiences and safety features.

Key OPEN questions

1) What’s the last-mile parcel delivery strategy for North America?

2) What’s Ford’s response to Brightdrop, GM’s bespoke delivery vehicle and business?

3) What’s the impact on our current programs

RESEARCH INFORMING POV

HMW learn about customer needs without having access to the customer?

This project focused on developing, first, a point of view before directly engaging a large Customer.

Since we were not talking to customers, we decided to talk to National account managers (NAMS) instead, who have a good working relationship with customers, and they have plenty of knowledge about what customers want.

Since we were not talking to customers, we decided to talk to National account managers (NAMS) instead, who have a good working relationship with customers, and they have plenty of knowledge about what customers want.

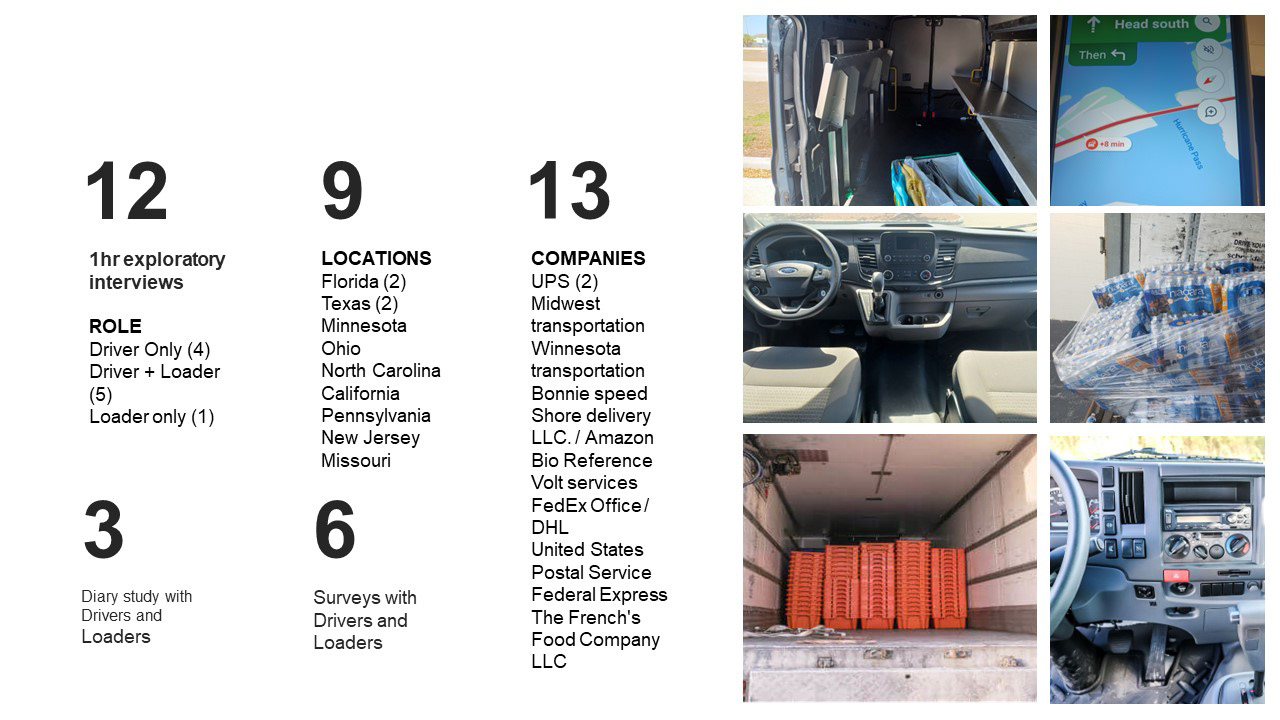

We also did Interviews with 12 drivers and loaders, 4 NAMS, diary studies for context, survey for validation of these takeaways.

CREATING A WIDE RANGE OF PROVOCATIONS

Fail fast - learn faster

At this stage of the project, I found myself juggling multiple workstreams simultaneously. I was creating a diverse array of stimuli, all of which were grounded in the extensive secondary research I had been conducting. Additionally, I actively engaged in primary research interviews to gain a firsthand understanding of the context. This direct engagement was crucial in refining my design provocations for further testing. Simultaneously, I was constantly synthesizing all this information, using it to inform and evolve new design stimuli.

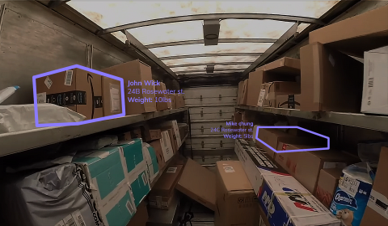

Non-interface = ideal interface?

I was excited by a hypothesis that a lack of an interface is the best interface in this case. What if the driver doesn't have to interact with any interface at all, and an invisible system scans packages on its own, integrating into the driver's workflow?

I sketched out some proposals and collaborated with a unity developer in the RnD division to help me make a prototype, for a augmented reality-based, package retrieval system.

To my surprise, participants responded poorly to most of these designs and especially to more high-tech concepts. What they were looking for were incremental changes to the navigation system and secure shelving.

research insights

What matters most to customers (the big 4)

In our research on drivers and loaders, we found that buffering volatility is crucial for them, as they frequently deal with factors beyond their control, such as fluctuating weather, staffing shortages, and varying road conditions. Interestingly, we observed that systems and protocols meant to boost their productivity often inadvertently increase their cognitive stress. Additionally, their long and physically demanding workdays, characterized by repeatedly entering and exiting their vehicles and lifting heavy objects, significantly contribute to their physical stress.

What matters most to customers

(as learned from NAM sessions)

From our interviews with national account managers, we discovered that customers often lacked trust in Ford's software, preferring empty trucks to integrate their fleet management software. This preference directly conflicted with Ford's aspirations to expand their digital offerings. However, we noted that small to medium-scale operations showed a significant interest in Ford's Telematics software solutions.

What matters most to staff on the ground (drivers and loaders)

We learned that for our customers, buffering volatility involves managing external supply chain shocks. Additionally, there's a strong interest in electrifying their fleet to align with sustainability goals and benefit from the lower maintenance costs of electric vehicles. Managing liability costs, including those arising from accidents or damage to vehicles and drivers, remains a constant concern.

SOLUTION AREAS

What's needed to be effective in the last mile space?

Three solution areas

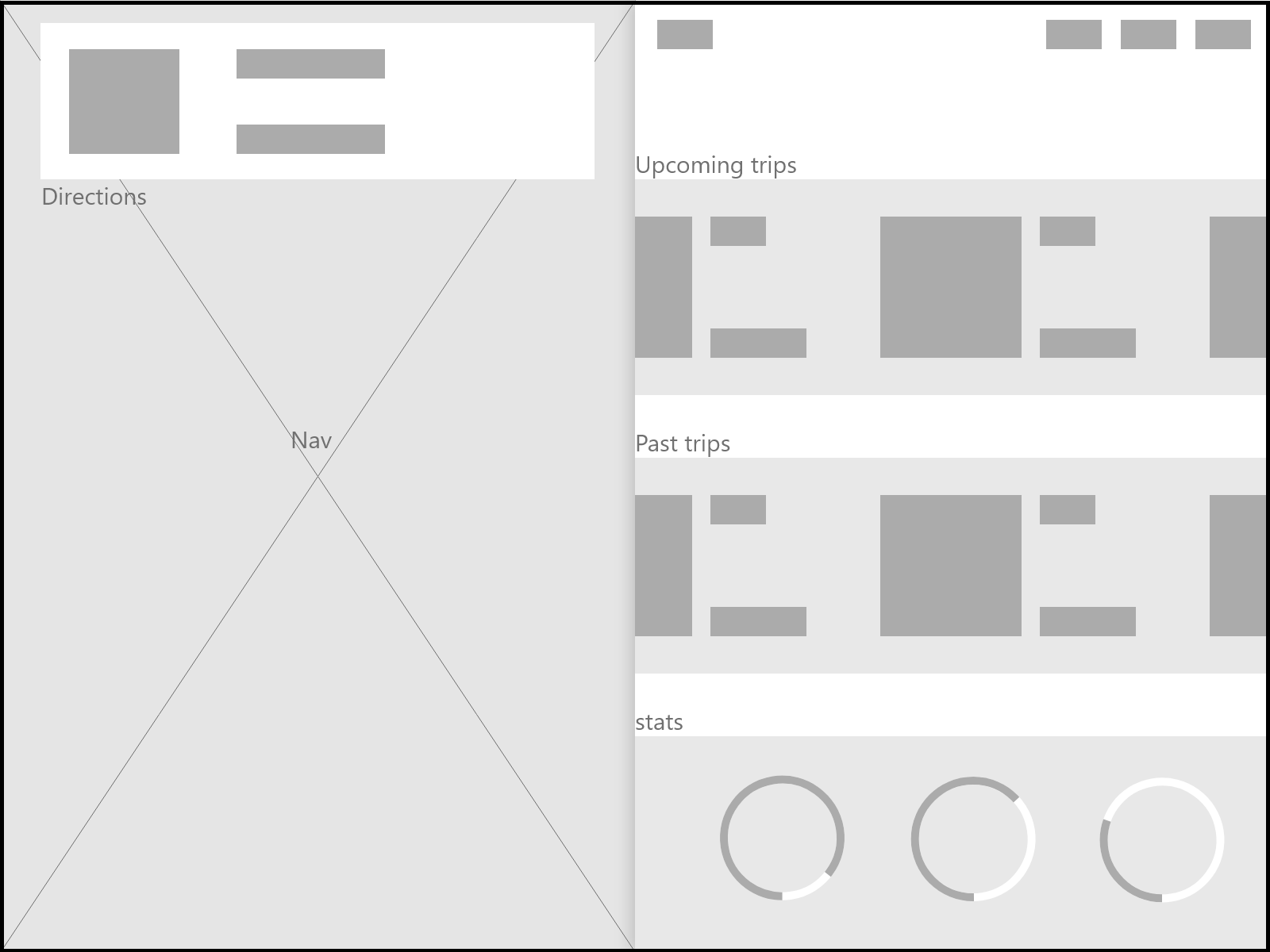

driver/loader journey map

This user journey map outlines the entire shift of a driver and loader, from starting their shift, making a delivery, and returning to the warehouse. It highlights pain points and potential opportunities for improvement throughout their journey, as well as identifying and celebrating the high points experienced along the way.

Created 50+ concepts in the now, near, and far framework

Solution areas included –

• Physical design

• Software design and tools

• System design

• AI, robotics, and emerging technologies

DESIGN SOLUTIONS

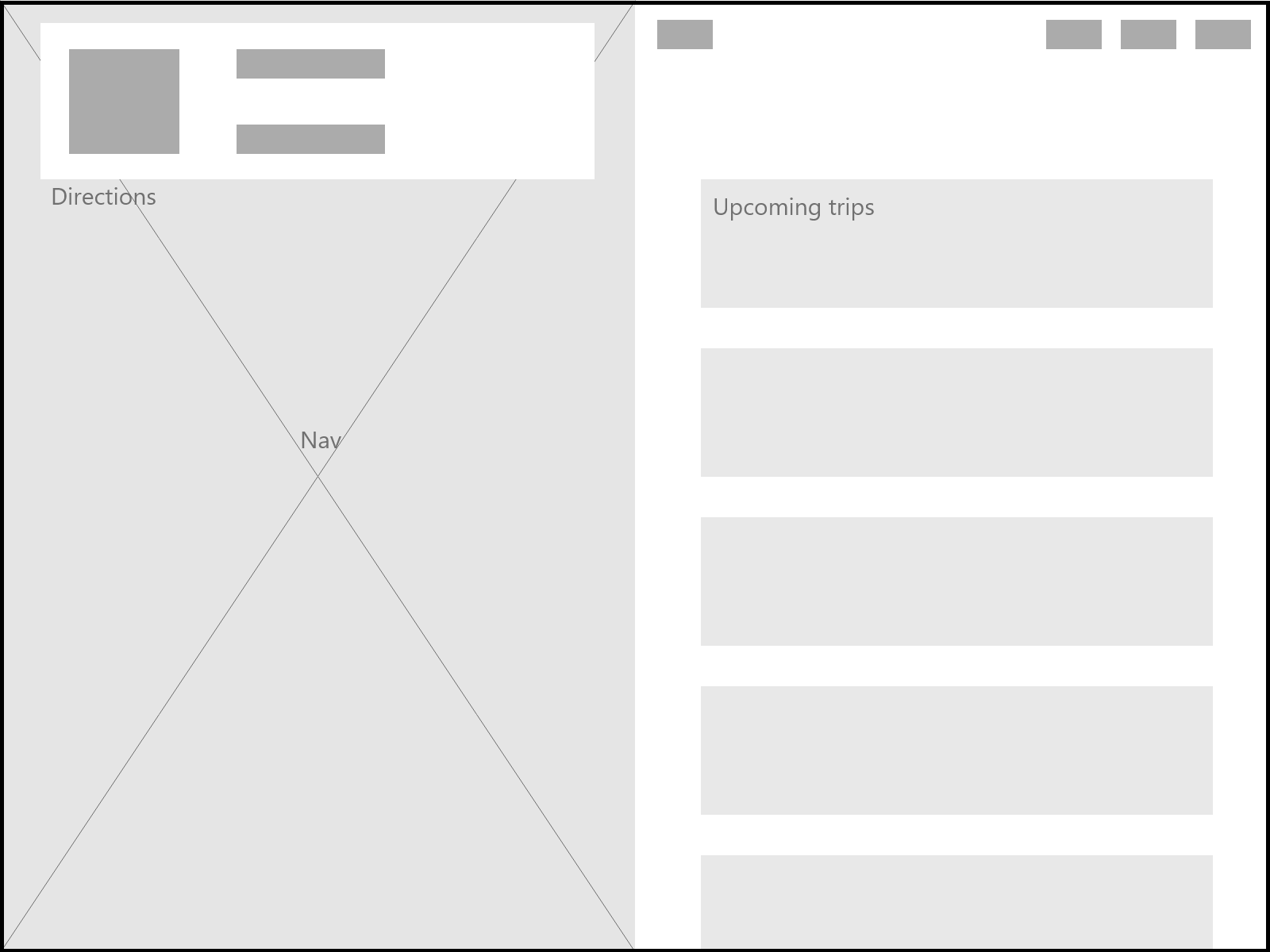

1. META-TAGGING ADDRESSES

What if drivers could know ahead of time, exactly what to expect before approaching an address?

Context

Delivery drivers often face numerous unforeseen situations that pose a significant threat to their safety and well-being, rendering their jobs inherently risky. They encounter aggressive drivers, hazardous weather conditions, unfamiliar neighborhoods, and even potential encounters with criminals. Navigating through these challenges demands resilience, quick thinking, and a commitment to staying vigilant at all times.

Delivery drivers often face numerous unforeseen situations that pose a significant threat to their safety and well-being, rendering their jobs inherently risky. They encounter aggressive drivers, hazardous weather conditions, unfamiliar neighborhoods, and even potential encounters with criminals. Navigating through these challenges demands resilience, quick thinking, and a commitment to staying vigilant at all times.

“Safety is anything that helps with backing in, running into things.

There’s always interest in safety.” – UPS NAM

There’s always interest in safety.” – UPS NAM

“I was bitten by a dog while delivering packages.” – Driver

Exploration

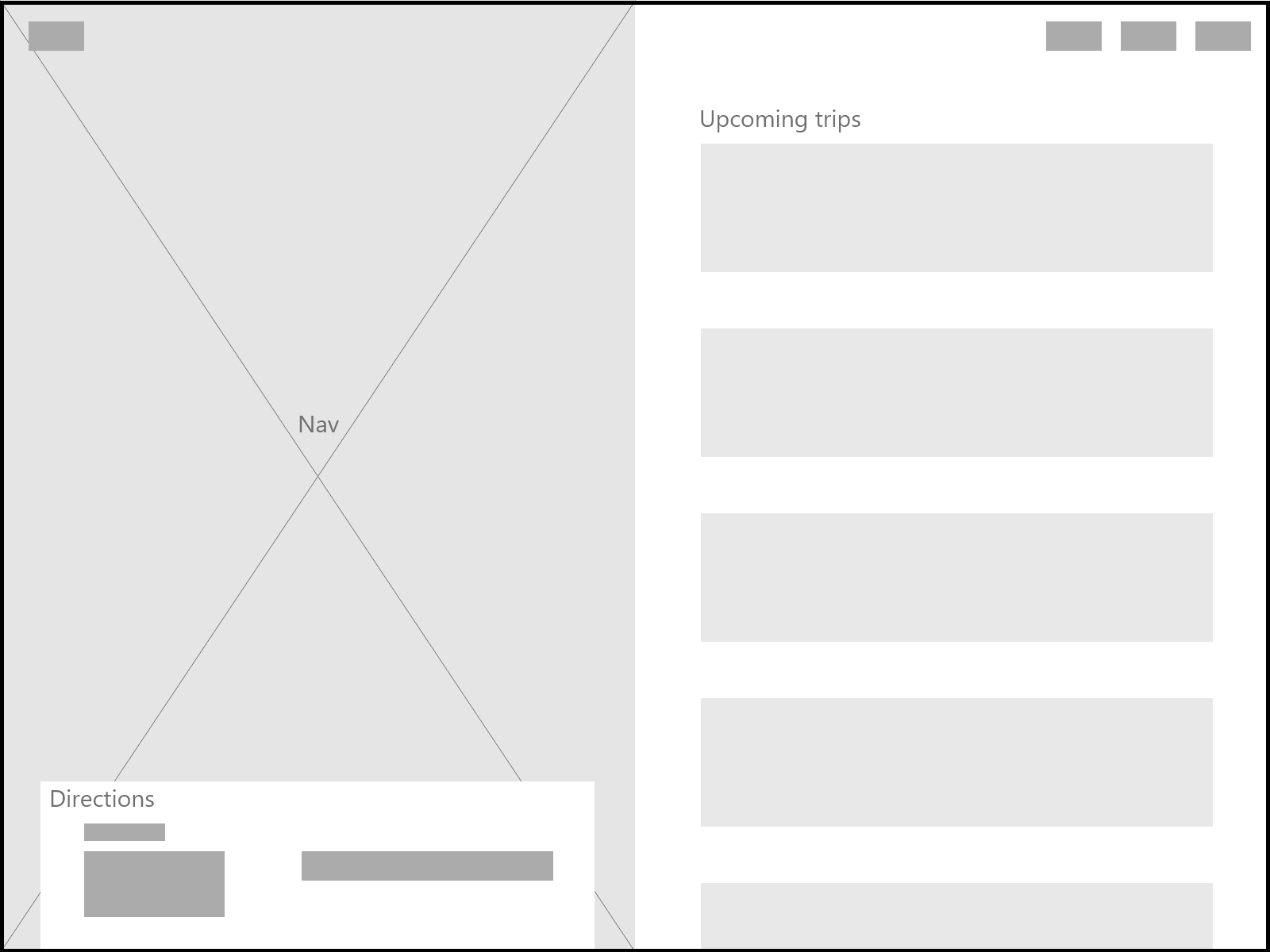

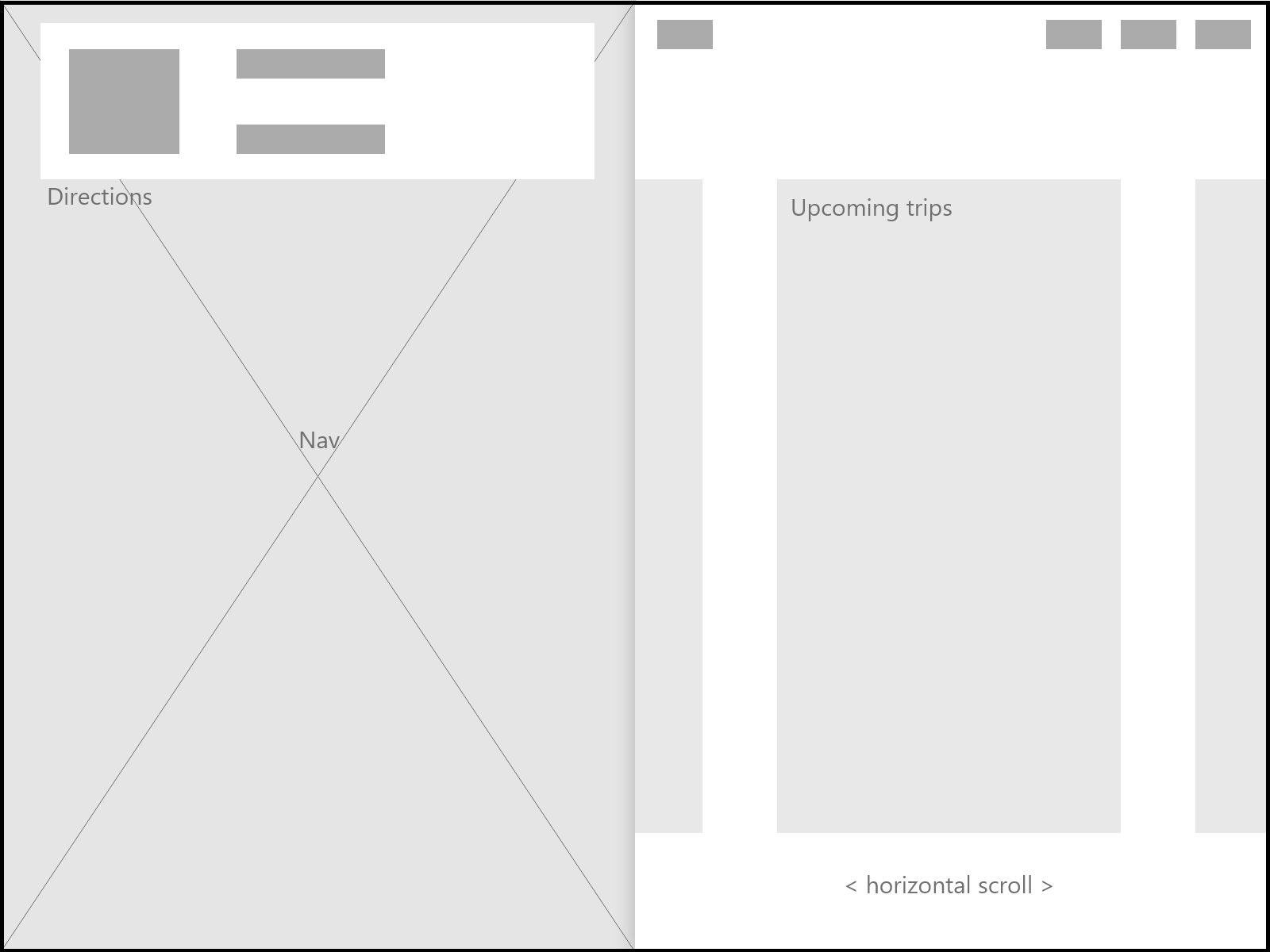

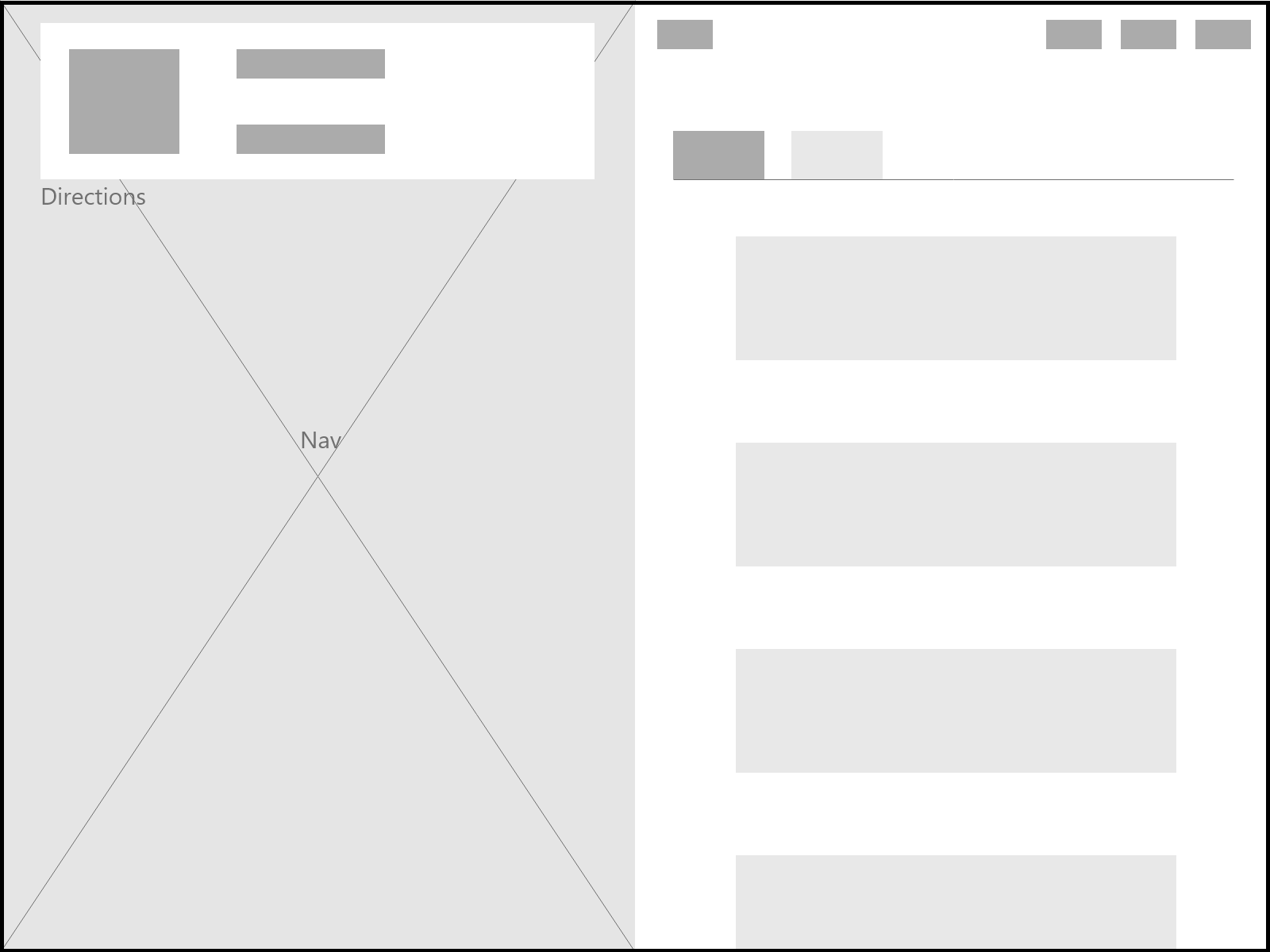

I started mocking up a meta-tagging feature that builds up on existing features built into route planning software. Drivers are currently indicated delivery instructions set up by the recipient. But if drivers could collectively add address-specific info, it would enable them to do their job better and safer. Shown below are wireframes and mock-ups that were taken to research as stimuli.

I started mocking up a meta-tagging feature that builds up on existing features built into route planning software. Drivers are currently indicated delivery instructions set up by the recipient. But if drivers could collectively add address-specific info, it would enable them to do their job better and safer. Shown below are wireframes and mock-ups that were taken to research as stimuli.

Stimuli for research

Research participants liked the functionality of the proposal. They also liked the overall layout but wanted more focus on the navigation. Some of the feedback is captured below -

1. Place the navigation element closer to the driver. They anticipated only interacting with the list view, while parked.

2. Participants preferred to see the address upfront rather than the customer's name.

3. While they loved the suggestion of meta-tagging, they also wanted to see delivery notes left by address

4. The 'In-progress' and the 'completed' tab were well received as there is a good sense of completion if you can track progress. Participants expressed a need for a more visual representation of the progress which was always visible.

5. The 'check' icons were causing some confusion and people did not respond to them well.

6. Participants had trouble figuring out what the '+' symbol was for meta-tagging.

Solution

Adding an option to add meta tags to individual addresses. Drivers can add icons indicating special instructions. The tags are synced with telematics and are available for all drivers to see. It gives options as to whether the property has a guard dog, a flight of stairs, CCTV cameras, or side/back entry.

Adding an option to add meta tags to individual addresses. Drivers can add icons indicating special instructions. The tags are synced with telematics and are available for all drivers to see. It gives options as to whether the property has a guard dog, a flight of stairs, CCTV cameras, or side/back entry.

The design also incorporated a subtle progress bar at the top, providing drivers with a tangible sense of completion and accomplishment. For added convenience, we included quick-access options for restrooms and gas stations. Furthermore, a dropdown menu was implemented for address-specific instructions, displaying customer-added instructions on the left and driver-added meta tags on the right. All features were clearly labeled to ensure easy comprehension.

Prototype

2. VAN - VENDING MACHINE

Patent pending

Patent pending

What if drivers could do all tasks without leaving the cabin?

Context

Delivery drivers need to constantly step in and out of the van to fetch packages. Even though packages are organized by zones, they often get shuffled during the drive making it harder to find them.

Delivery drivers need to constantly step in and out of the van to fetch packages. Even though packages are organized by zones, they often get shuffled during the drive making it harder to find them.

“ My workforce can get in and get out of their vehicles, access front and rear cabins, standing.”

– Fleet manager

– Fleet manager

“Step-in, walk-in heights are critical. Anything to shave a second, they’re on it." – UPS NAM

Solution

A fully automated bin sorting system fully utilizes the cargo area. Packages are presorted into bins at the warehouse and automatically loaded into the van. Bins containing the right package for the stop are brought out into the cabin

A fully automated bin sorting system fully utilizes the cargo area. Packages are presorted into bins at the warehouse and automatically loaded into the van. Bins containing the right package for the stop are brought out into the cabin

Physical Implications

Vehicle packaging to be more boxy and less tapered up top to accommodate more bins. The vehicle is compatible with a conveyor belt system to load up bins

Vehicle packaging to be more boxy and less tapered up top to accommodate more bins. The vehicle is compatible with a conveyor belt system to load up bins

Tech enablers

Bin sorting system to be linked with onboard GPS and fleet management system. Tagging system to identify bins and packages, either passive or active with the use of cameras.

Bin sorting system to be linked with onboard GPS and fleet management system. Tagging system to identify bins and packages, either passive or active with the use of cameras.

3. LOAD TIME ZERO

Patent pending

Patent pending

What if you could load the van in no time?

Context

Drivers and loaders spend a lot of time at the beginning of each shift loading up packages into the van. This requires constant ingress and egress causing a lot of wear on the body, not to mention extra time.

Drivers and loaders spend a lot of time at the beginning of each shift loading up packages into the van. This requires constant ingress and egress causing a lot of wear on the body, not to mention extra time.

“ My workforce can get in and get out of their vehicles, access front and rear cabins, standing.”

– Fleet manager

– Fleet manager

“Step-in, walk-in heights are critical. Anything to shave a second, they’re on it." – UPS NAM

Solution

Load time zero is a cart and ramp offering. Presorted packages are carried to the vehicle on carts. The driver simply pushes the loaded cart into the van and locks it in place. This cuts down the time to load the van from ~20 minutes to nearly zero. Packages are sorted according to the route and stop. In situations where a loading dock isn’t present a fully adjustable ramp serves that function. The ramp can be folded up for easy storage and maneuverability. The ramp stays at the warehouse

Load time zero is a cart and ramp offering. Presorted packages are carried to the vehicle on carts. The driver simply pushes the loaded cart into the van and locks it in place. This cuts down the time to load the van from ~20 minutes to nearly zero. Packages are sorted according to the route and stop. In situations where a loading dock isn’t present a fully adjustable ramp serves that function. The ramp can be folded up for easy storage and maneuverability. The ramp stays at the warehouse

Physical Implications

Assumes space/ground between vehicle and warehouse

Vehicle load floor compatible with rolling rack

The vehicle rear is compatible with the ramp, ideally, the floor is flat

Hard retention points in vehicle racks

Power, mounting points for rack attachment location.

System-level implementation in the customer warehouse logistics process

Assumes space/ground between vehicle and warehouse

Vehicle load floor compatible with rolling rack

The vehicle rear is compatible with the ramp, ideally, the floor is flat

Hard retention points in vehicle racks

Power, mounting points for rack attachment location.

System-level implementation in the customer warehouse logistics process

Tech enablers

Rack and cart that mounts to vehicle side walls through mounting points

Potential to add a strip, pick, and LED lights on the cart to enable the quick and consistent organization of parcel

Rack and cart that mounts to vehicle side walls through mounting points

Potential to add a strip, pick, and LED lights on the cart to enable the quick and consistent organization of parcel

CONCEPT MATRIX ACROSS OPPORTUNITIES AND SOLUTION AREAS

PROJECT OUTCOME

Presented to stakeholders and program leadership to decide on an implementation plan.

2 design directions got absorbed into programs

It served as a tool to engage a large customer

Filed 2 patents

Built new partnerships in RnD and various other organizations

LEARNINGS

Learned a lot about last-mile logistics and pain points of logistics workflows

Research methods and interviewing best-practices

Leveraging existing mental models to craft familiar interactions

Also learned about using Mixed reality-based technologies in commercial applications